- Plastic injection preform mould manufacturer code#

- Plastic injection preform mould manufacturer professional#

The National Association for PET Container Resources (NAPCOR) defines PET as: "Polyethylene terephthalate items referenced are derived from terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol, wherein the sum of terephthalic acid (or dimethyl terephthalate) and mono ethylene glycol reacted constitutes at least 90 percent of the mass of monomer reacted to form the polymer, and must exhibit a melting peak temperature between 225 ☌ and 255 ☌, as identified during the second thermal scan in procedure 10.1 in ASTM D3418, when heating the sample at a rate of 10 ☌/minute." ĭepending on its processing and thermal history, polyethylene terephthalate may exist both as an amorphous (transparent) and as a semi-crystalline polymer.

Plastic injection preform mould manufacturer code#

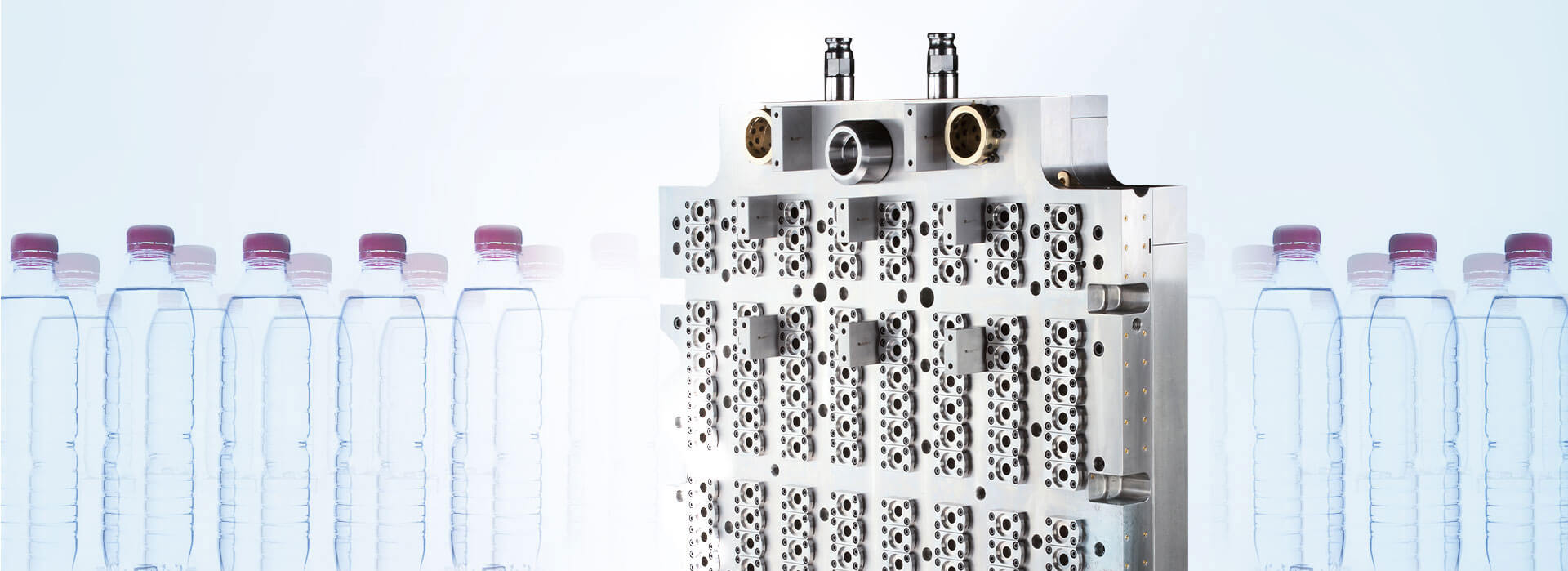

PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). PET consists of repeating (C 10H 8O 4) units. Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym PET is generally used in relation to packaging. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In 2016, annual production of PET was 56 million tons. And customized service is also offered.Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. We have introduced advanced equipment and technology into our factory in order to offer customers quality mould with unique design. Yuno Mould is a famous enterprise in offering quality 96 cavities water preform mould made in China, which is also one of the leading manufacturers and suppliers of PET perform moulds. High hardness steel such as S 136 steel, Short cycle time, More mould shots, Easier Maintenance. Why choose us HIGHER QUALITY & GOOD PRICE.

Plastic injection preform mould manufacturer professional#

The screw neck is made and inspected strictly by the standard of Coca cola and the screw neck has been up to the standard of Coca cola.Īfter-Sales Service Technologists professional in after-sales line and excellent credit assures stable operation of the machines.,every question will answer within 24hours. Perfect Inspection Method Inspection tools include projector, hardness tester, stress tester, eccentric tester, electric balance and other inspection tools. Offering temperature controller and voltage controller according to customers' requirement German intelligent temperature controller (PID continuous power controlling). All of these increases processing precision, good interchangeability and low eccentricity = 0.10mm (perform length= 100).Įlectric Heating Components 1. Īdvanced Processing Equipment Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. We supply special technology training and other good after-sales service.After ten years effort, it has grown steadily and turned into a Professional PET preform mold supplier. Various kinds of processing equipment and detection measurement instrument are imported, as well as special drawing soft is applied in designing performs, samples and manufacturing testing mold. We invite many technical committee members and senior professors in mould line are as the technical consultants for our company.Yuanneng always focuses on its innovation and development. Product Description YUNO MOULD, specialized in manufacturing PET Preform Preform injection molding system, consists of technologists with rich experience, and senior engineers with master's degree and professional in 3D.

0 kommentar(er)

0 kommentar(er)